Understanding Vapor Tight Lighting

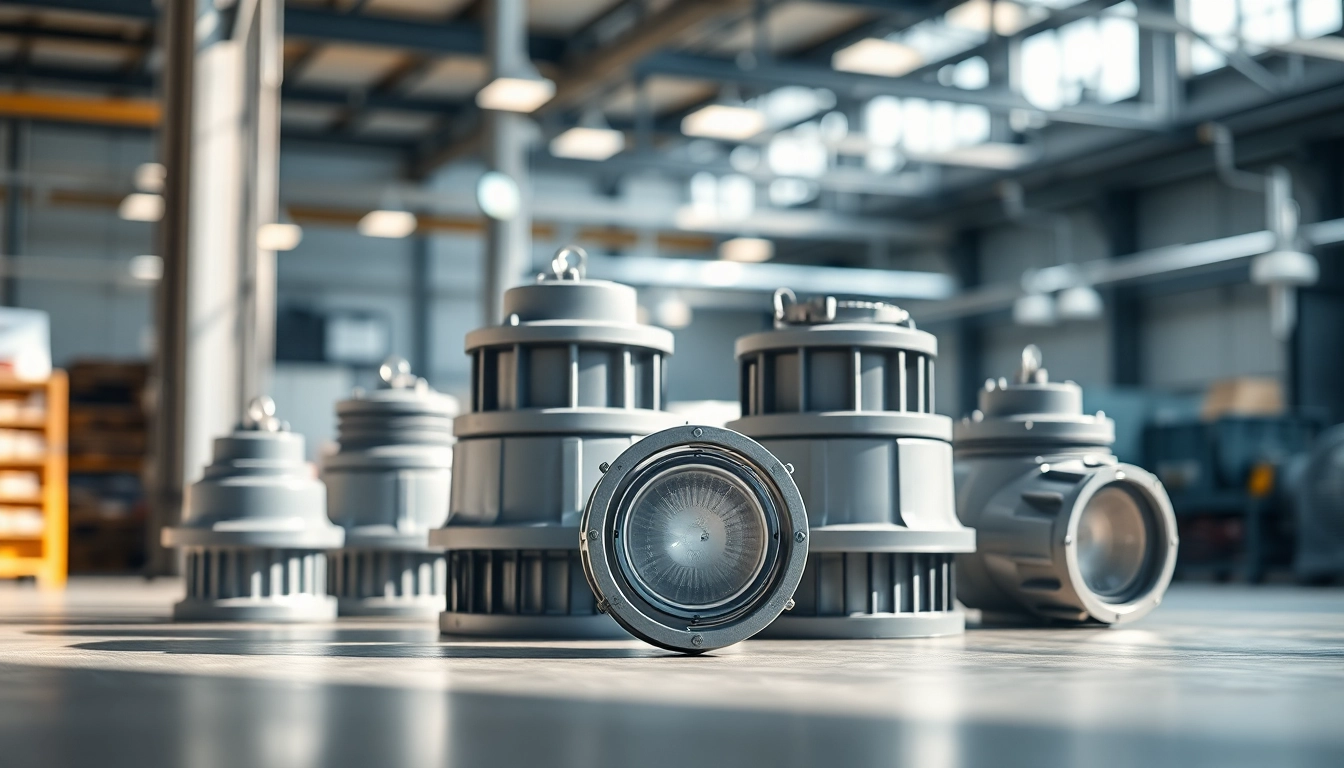

In environments where moisture, dust, and debris are prevalent, traditional lighting solutions often fail to perform optimally. This is where Vapor Tight lighting fixtures come into play, offering a robust solution designed to withstand challenging conditions. This article delves into the world of Vapor Tight lighting, exploring its definition, features, benefits, applications, installation, maintenance, comparative analysis, and the future trends shaping its technology.

Definition and Key Features of Vapor Tight

Vapor Tight lighting fixtures are specifically engineered to provide reliable illumination in wet, humid, dusty, or hazardous environments. They are constructed with durable materials that prevent moisture and contaminants from entering the housing, ensuring longevity and performance. Key features of Vapor Tight lighting include:

- Sealed Construction: The design incorporates gaskets and seals that protect internal components from moisture and dust.

- Impact Resistance: These fixtures are often made with shatter-resistant materials to withstand impacts and reduce the risk of breakage in industrial settings.

- Energy Efficiency: Many Vapor Tight configurations use LED technology, which significantly lowers energy consumption compared to traditional incandescent or fluorescent options.

- Versatile Mounting Options: They come with various mounting options suitable for ceilings, walls, or even suspended installations.

Why Choose Vapor Tight Fixtures?

When it comes to choosing lighting for specialized environments, Vapor Tight fixtures stand out for several reasons:

- Durability: Their resilient construction ensures they can withstand exposure to harsh elements, making them ideal for industrial, agricultural, and outdoor applications.

- Lower Maintenance Costs: The sealed design reduces the risk of failure due to moisture or contaminants, leading to fewer replacements and lower overall maintenance expenses.

- Safety: With compliance to safety standards, these fixtures minimize fire hazards associated with traditional lighting in damp areas.

- Compliance: Often designed to meet stringent industrial and safety regulations, they ensure that workplaces remain safe and illuminated.

Common Applications for Vapor Tight

Vapor Tight fixtures are utilized in various settings where exposure to dampness and debris is frequent:

- Parking Garages: Their durability and moisture-resistant features make them ideal for providing illumination in underground or outdoor parking environments.

- Food Processing Facilities: The sealed nature helps maintain hygiene and safety in areas where food is produced and processed.

- Agricultural Buildings: These fixtures excel in barns and greenhouses, where humidity levels can be high and proper lighting is critical for plant growth.

- Utilities: Vapor Tight fixtures are often found in water treatment plants, power plants, and other utility settings where environmental conditions are unpredictable.

Benefits of Using Vapor Tight Lighting

Durability and Longevity Advantages of Vapor Tight

One of the primary advantages of Vapor Tight lighting is its robustness. Designed to endure tough conditions, these fixtures provide a long lifespan, often exceeding traditional lighting options by factors of two or three times. The materials used in Vapor Tight construction, such as polycarbonate and high-grade aluminum, resist corrosion, while improved gasket technology prevents moisture ingress. This durability not only enhances safety but significantly decreases the total cost of ownership through lower replacement rates.

Energy Efficiency Factors of Vapor Tight

Energy efficiency is a growing concern across all industries, impacting operational costs and environmental sustainability. Vapor Tight fixtures often leverage advanced LED technology, which consumes considerably less power than conventional sources:

- Reduced Energy Consumption: LEDs use up to 80% less energy than incandescent bulbs while providing the same lighting output.

- Longer Lifespan: With expected lifespans exceeding 50,000 hours, LED Vapor Tight fixtures reduce the frequency of replacements and the associated labor costs.

- Lower Heat Emission: LEDs emit less heat, improving energy efficiency and reducing the load on HVAC systems.

Safety Standards Compliance with Vapor Tight

Safety plays a critical role in the selection of lighting fixtures, especially in commercial and industrial environments. Vapor Tight fixtures are designed to comply with various safety standards, including:

- UL and CE Certification: Certification by recognized safety organizations ensures that the lighting meets stringent safety and operational standards.

- Classified Ratings: Many Vapor Tight fixtures are rated for use in hazardous locations, meaning they can safely operate in environments with flammable gases and vapors.

- Increased Visibility: Proper illumination enhances visibility, thereby reducing the risk of accidents and injuries in workplaces.

Installation and Maintenance Tips for Vapor Tight

Best Practices for Installing Vapor Tight

Installing Vapor Tight fixtures correctly is essential for optimizing their performance and longevity. Follow these best practices:

- Choose the Right Location: Install fixtures in areas with high moisture or dust levels while adhering to local building codes and regulations.

- Secure Mounting: Ensure that the fixtures are securely mounted to prevent vibrations or movements that could impact the gaskets and seals.

- Follow Manufacturer Instructions: Always adhere to the manufacturer’s guidelines for installation to ensure compliance with safety standards and warranty protections.

- Proper Wiring: Use appropriate cables and seal all electrical connections to prevent moisture ingress and short circuits.

Regular Maintenance Checklist for Vapor Tight

While Vapor Tight fixtures are built for durability, regular maintenance is key to ensuring continued performance and efficiency:

- Inspect Seals and Gaskets: Regularly check seals for wear or damage, replacing them as necessary to maintain their waterproofing capabilities.

- Cleansing: Dust and debris can gather on the surface, so cleaning the lenses and housing with a gentle cleaner can improve brightness and efficiency.

- Electrical Check: Verify that electrical connections are secure and free from corrosion or rust, which can impede performance and safety.

- Lighting Calibration: Periodically measure lighting levels to ensure they meet the required standards for workplace safety and effectiveness.

Troubleshooting Common Vapor Tight Issues

Even with durable products, issues may arise over time. Being aware of common problems can aid quick resolution:

- Flickering Lights: This can indicate loose connections or failing LEDs. Check wiring and replace any defective bulbs.

- Moisture Accumulation: If moisture appears inside the fixture, inspect seals for damage and replace promptly to prevent electrical failures.

- Unresponsive Lights: First, check the power source and connections. If all else appears normal, consider replacing the fixture.

Comparing Vapor Tight with Other Lighting Options

Vapor Tight vs. Standard Lighting

When comparing Vapor Tight fixtures to standard lighting options, several distinct differences emerge:

- Moisture Protection: Standard lighting typically lacks the waterproof and dustproof qualities of Vapor Tight fixtures, making them unsuitable for certain environments.

- Durability: Vapor Tight fixtures are built to withstand impacts and harsh conditions, while standard fixtures usually are not designed for such scenarios.

- Cost Over Time: Though the initial costs might be higher for Vapor Tight, the long-term savings in maintenance and energy consumption can be substantial.

When to Choose Vapor Tight Over Alternatives

In certain scenarios, the choice for Vapor Tight fixtures is clear:

- High-Humidity Areas: Spaces such as washrooms, kitchens, and food processing plants benefit immensely from the moisture barrier provided by Vapor Tight lighting.

- Industrial Settings: Factories, warehouses, and manufacturing areas often have conditions unsuitable for standard lighting options.

- Outdoor Applications: Areas exposed to rain, snowfall, or extreme dust need the protection that only Vapor Tight fixtures can provide.

Cost Analysis of Vapor Tight Compared to Other Lighting

Investing in Vapor Tight fixtures may seem costlier upfront; however, a more comprehensive cost analysis indicates long-term advantages:

- Initial Investment: Standard fixtures can be cheaper, but they often require more frequent replacements and repairs in challenged environments.

- Energy Efficiency: The lower power consumption of LED-integrated Vapor Tight fixtures can lead to notable cost savings on electricity bills.

- Maintenance Costs: Reduced need for maintenance due to weatherproofing leads to lower operational costs overall.

Future Trends in Vapor Tight Technology

Innovations in Vapor Tight Design

As technology evolves, so too does the design and functionality of Vapor Tight fixtures. New trends are revolutionizing how they operate:

- Smart Lighting: Integration of IoT technology is paving the way for smart Vapor Tight fixtures that can communicate with building management systems for real-time monitoring and adjustments.

- Advanced Materials: Innovations in materials science are leading to even more durable, lightweight, and efficient fixtures that can withstand harsher conditions.

- Customizable Features: Fixtures are becoming more versatile, offering options for adjustable color temperatures and lighting intensities.

Impact of Smart Technology on Vapor Tight

Smart technology is transforming traditional lighting paradigms. In the realm of Vapor Tight solutions, this means:

- Improved Control: Wireless control systems allow for remote management of light levels, saving energy and enhancing convenience.

- Data Collection: Smart fixtures can analyze usage patterns and provide valuable insights into energy consumption, helping facilities optimize their lighting strategy.

- Predictive Maintenance: These technologies can alert maintenance teams to potential issues before they become significant problems, furthering the benefits of Vapor Tight installations.

Predictions for Vapor Tight Market Growth

With ongoing advancements and increased awareness of sustainable and efficient lighting solutions, the Vapor Tight market is poised for significant growth:

- Increased Demand: As more industries recognize the value of Vapor Tight fixtures, their adoption is expected to rise substantially in both new construction and retrofit projects.

- Technological Advancements: Continued research and development will yield improved performance and efficiency, making these fixtures even more appealing.

- Sustainability Trends: As environmental consciousness rises, businesses are likely to favor energy-efficient solutions, further driving the Vapor Tight market.